Monika Jatiwal, Chetna Arora and Aastha Gupta

CSE Department, Dronacharya college of Engineering, Gurgaon affilated to MDU, India.

Article Publishing History

Article Received on :

Article Accepted on :

Article Published :

Article Metrics

ABSTRACT:

This paper will describe the technology RFID that is Radio Frequency Identification and gives an overview of the current state of the art in the radio frequency identification (RFID) technology. It also tell how does it work and what are its applications and problems in RFID technology ? This paper presents a few applications that are possible using RFID technology such as locating lost items, tracking moving objects, and others . The convergence of lower cost and increased capabilities made businesses take a hard look at what RFID can do for them. Also its various types are described here.

KEYWORDS:

Radio frequency; Technology; Application

Copy the following to cite this article:

Jatiwal M, Arora C, Gupta A. A Survey on Radio Frequency Identification (RFID). Orient. J. Comp. Sci. and Technol;6(4)

|

Copy the following to cite this URL:

Jatiwal M, Arora C, Gupta A. A Survey on Radio Frequency Identification (RFID). Orient. J. Comp. Sci. and Technol;6(4). Available from: http://www.computerscijournal.org/?p=2863

|

Introduction

Radio frequency identification uses a semiconductor (micro-chip) in a tag or label to transmit stored data when the tag or label is exposed to radio waves of the correct frequency. RFID tags, or simply “tags”, are small transponders that respond to queries from a reader by wirelessly transmitting a serial number or similar identifier. They are heavily used to track items in production environments and to label items in supermarkets. Most RFID tags store some sort of identification number; for example a customer number or product SKU (stock-keeping unit) code.

Disadvantages of barcode

Pricing Discrepancies and Scanning Problems

When discounts apply to bar-coded merchandise, store employees may forget to to confusion and delays at the checkout counter, inconveniencing the customer, the checkout clerk, and other customers waiting in line. If a barcode can’t be scanned, for any reason, the clerk must then read the corresponding numeric code and enter it manually. Because clerks have become used to scanning barcodes quickly and automatically, without any additional effort on their part, their lack of practice in manual code entries may potentially cause them to be slow and/or inaccurate in entering the information, further delaying the checkout process.

Label Damage

Barcodes that are printed on a torn section of packaging, or that have been smeared, smudged or otherwise damaged, will present additional scanning problems. If the corresponding numeric code is also illegible due to damage, the checkout process can be significantly delayed while another package of the same merchandise is located and brought to the checkout counter for scanning.

Financial and Equipment Costs

For businesses that are not already equipped for barcode checkout, the cost of the equipment necessary to implement the new system can be prohibitive. Other delays can occur in training employees to adapt to new equipment, and expensive printers must be purchased to print coded labels for any merchandise that doesn’t come prepackaged with a barcode already on it. Dot matrix and ink jet printers, for example, are generally incapable of printing finely-detailed barcodes.

Need for RFID

Problems with barcodes

- Mis-orientation, obstruction by dirt, mist, protrusions and damage all cause failed reads or misreads.

- They have to be read at line of sight, usually at distances below one meter.

- Scanners are delicate and expensive, causing problems for e.g , New Zealand sheep farmers.

- Very little data is stored and it is read-only and not secure or even covert.

- The image is relatively large and ugly. It is impossible to put a practicable barcode on, say an earring or a single wrap of candy because of appearance and the need for high accuracy printing, substrate stability, etc,.

- Simultaneous non-collision scanning of multiple images/products is near impossible.

- Ruggedized versions for e.g., high temperature, high abrasion is expensive – even more expensive than some RFID smart labels. The usual versions printed on paper or thin plastic packaging easily fail through crumpling or tearing.

If a barcode is not printed nearly perfectly, it may be difficult for a scanner to read correctly. ASP Microcomputers explains that if ink bleeds or smudges on a barcode, a scanner will not be able to identify it. If the lines of a barcode are not spaced correctly, it will be impossible to read. Ink bleeding can cause lines to appear closer together than they should be, as can using an incorrect font to print a barcode. Dirt or water damage can also cause lines to be distorted.

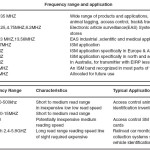

Active tags

Active RFID tags, which have both an on-tag power source and an active transmitter, offer superior performance. Because they are connected to their own battery, they can be read at a much higher range from several kilometers away. Because of their on-board power source, active tags operate at higher frequencies—commonly 455 MHz, 2.45 GHz, or 5.8 GHz. Readers can communicate with active RFID tags across 20 to 100 meters.

Disadvantages

- Power source makes them larger and more expensive, so active RFID systems typically work best on large item stacked over long distances.

- Active tags can remain dormant(not active) until they come in range of a receiver or can constantly broadcast a sign.

Passive tags

Passive tags are very inexpensive. Because of the inexpensive cost they become the basis of growth in RFID implementation. Passive tags have no power source and no on-tag transmitter, which gives them a range of less than 10-metres.

Difference between barcode and rfid barcode

RFID

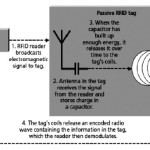

Working of passive tag

The communication between the reader and passive tag uses one of two methods to modulate the ID signal. Low-frequency (less than 100MHz) tags pass information by releasing energy from the capacitor to the tag coils The reader detects these varying waves and can use these variances to demodulate the code.

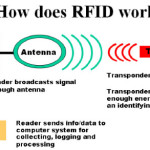

How RFID system works?

- All RFID systems have two integral parts: a tag, and a reader. Readers capture the information stored or gathered by the tag. The tag is composed of three parts (shown in the picture below):

- An antenna;

- A wireless “transducer” which may also be linked to a single silicon microchip unit containing memory storage; and

- An encapsulating material.

A tag reader can constantly broadcast its signal or broadcast it on demand. When a tag comes within the reader’s range, it receives an electromagnetic signal from the reader through the tag’s antenna. The tag then stores the energy from the signal in an on-board capacitor, a process called inductive coupling. When the capacitor has built up enough charge, it can power the RFID tag’s circuitry, which transmits a modulated signal to the reader. That return signal contains the information stored in the tag.

Applications of RFID

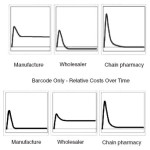

Supply chain management

In supply chain management, RFID tags are used to track products throughout the supply chain—from supplier delivery, to warehouse stock and tracking through customer billing. A database records product movement, which manufacturers or retailers can later query for location, delivery confirmation, or theft prevention. For this application, RFID basically serves as a replacement for the bar code scanners used to track products and shipments in similar ways.

Movement tracking

Moving objects can easily carry RFID tags, a common use is to track the movement of people and the information associated with them. Some hospitals now use tags on newborns, to ensure identification and to alert hospital staff should someone attempt to take the baby outside of the hospital without authorization.

Asset tracking

User can instantly determine the general location of tagged assets(like a healthcare facility, wheelchairs or IV pumps in, laptops) anywhere within the facility with the help of active RFID technology.

Warehouse

People tracking

People tracking system are used just as asset tracking system. Hospitals and jails are most general tracking required places. Hospital uses RFID tags for tracking their special patients. In emergency patient and other essential equipment can easily track. It will be mainly very useful in mental care hospitals where doctors can track each and every activity of the patient. The best use of the people tracking system will be in jails. It becomes an easy tracking system to track their inmates. Many jails of different US states like Michigan, California, and Arizona are already using RFID-tracking systems to keep a close eye on jail inmates.

Document tracking

This is most common problem. Availability of large amount of data and documents brings lots of problem in document management system. An RFID document-tracking system saves time and money by substantially reducing:

- Time spent searching for lost document.

- The financial and legal impact associated with losing documents.

Location tracking

If a given reader is assigned to a known location, it is possible to track the current place of a given uniquely identifiable item.

Advantages of RFID

- Tag detection not requiring human intervention reduces employment costs and eliminates human errors from data collection,

- No line-of-sight is required, tag placement is less constrained,

- RFID tags have a longer read range than barcodes,

- Tags can have read/write memory capability, while barcodes do not,

- An RFID tag can store large amounts of data additionally to a unique identifier,

- Unique item identification is easier to implement with RFID than with barcodes,

- Tags are less sensitive to adverse conditions (dust, chemicals, physical damage etc.),

- Many tags can be read simultaneously,

- RFID tags can be combined with sensors,

- Automatic reading at several places reduces time lags and inaccuracies in an inventory,

- Tags can locally store additional information; such distributed data storage may increase fault tolerance of the entire system,

- Reduces inventory control and provisioning costs,

- Reduces warranty claim processing costs

Security

An organization that implements RFID in its supply chain does not want competitors to track its shipments and inventory. People who use devices that carry personal financial information, such as credit card or other ID numbers, do not want others to access their accounts. These are significant security weakness in RFID.

Conclusion

The paper gave an overview of the current state and trends of RFID technology RFID, a technology existing for years, has potential loses in a variety of applications. It can be seen that especially enterprises in complex supply chains will benefit from RFID, once the application difficulties are overcome..

References

- http://www.rfidinternational.com.

- Shutzberg L., 2004: Radio Frequency Identification (RFID) In the Consumer Goods Supply Chain, Rock-Tenn Company, www.packagingdigest.com/newsite/Online/RFID_IWP.pdf.

- http://RFID.nordic.se.

- www.rfidjournalevents.com

This work is licensed under a Creative Commons Attribution 4.0 International License.